CNC milling is a computer-controlled process that involves using cutting tools to remove a portion of the workpiece. Its basic setup includes a workbench and cutting tools attached to the spindle.

The workpiece is placed on the workbench of the m...

CNC turning is a manufacturing process in which a material rod is fixed in a chuck and rotated, while tools are fed into the workpiece to remove the material and form the desired shape. It can produce small and large batches of components.

Not on...

Metal sheet metal processing is called sheet metal processing. For example, using sheet metal to make chimneys, iron barrels, oil tanks, ventilation pipes, elbows, small ends, Tianyuan places, funnel-shaped structures, etc. The main processes include...

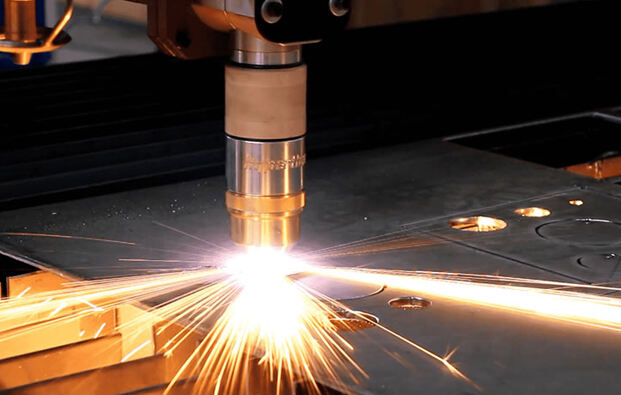

Laser cutting: Using a high-power density laser beam to irradiate the material being cut, high-energy laser pulses locally heat the material in small areas, and the energy radiated by the laser diffuses through the internal diffusion of the material ...

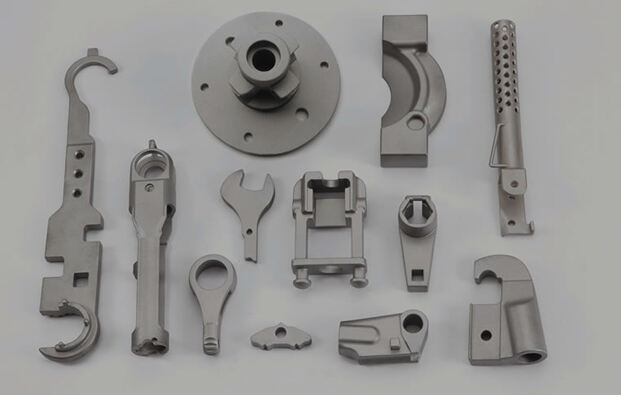

Precision casting is one of the casting methods. Compared with traditional casting processes, precision casting is a special casting method. It can obtain relatively accurate shapes and high casting accuracy.

The use of precision casting can save...

Die casting is a metal casting process that utilizes the inner cavity of the mold to apply high pressure to the melted metal. Molds are usually made from alloys with higher strength, and this process is somewhat similar to injection molding.

Wide...

Precision forging is an advanced forging method that improves the accuracy of forgings and reduces surface roughness. The advantage of this method is that it reduces the machining allowance and dimensional tolerance of the forging, and can make the f...

By using some physical, chemical, mechanical, or composite methods to make the metal surface have a different organizational structure, chemical composition, and physical state from the matrix, thereby enabling the treated surface to have different p...