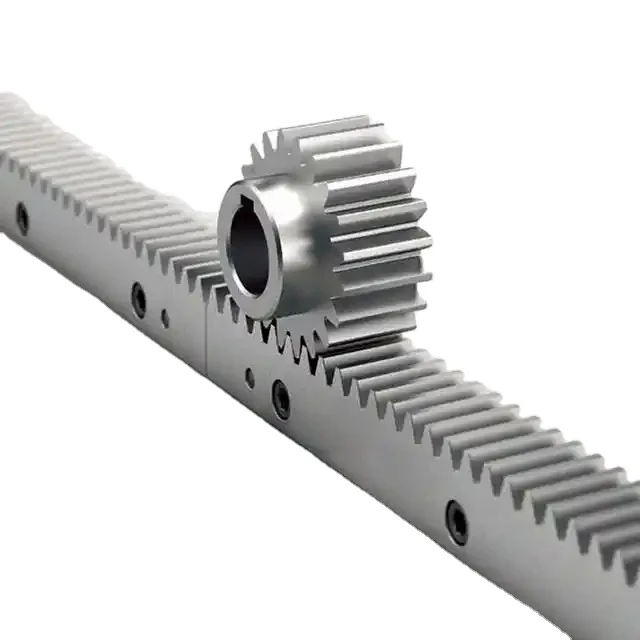

Die-Casting

Die casting is a metal casting process that utilizes the inner cavity of the mold to apply high pressure to the melted metal. Molds are usually made from alloys with higher strength, and this process is somewhat similar to injection molding.

Widely used and widely used: common die-cast automotive parts, die-cast automotive engine parts, die-cast air conditioning parts, die-cast gasoline engine cylinder heads, die-cast valve rocker arms, die-cast valve supports, die-cast decorative parts, die-cast guardrail parts, die-cast wheels, and other parts.

Die casting has the following three advantages: good product quality, high dimensional accuracy of castings, generally equivalent to 6-7 levels, and even up to 4 levels; Good surface finish, generally equivalent to 5-8 grades; The strength and hardness are relatively high, and the strength is generally increased by 25-30% compared to sand casting, but the elongation is reduced by about 70%; Stable size and good interchangeability; Can be used for die-casting thin-walled and complex castings.

We can provide customers with services with high production efficiency and machine productivity, precise size of produced die castings, and smooth surfaces. Generally, it is used directly without mechanical processing, or the processing volume is very small, which not only improves the metal utilization rate, but also saves assembly time and metal.