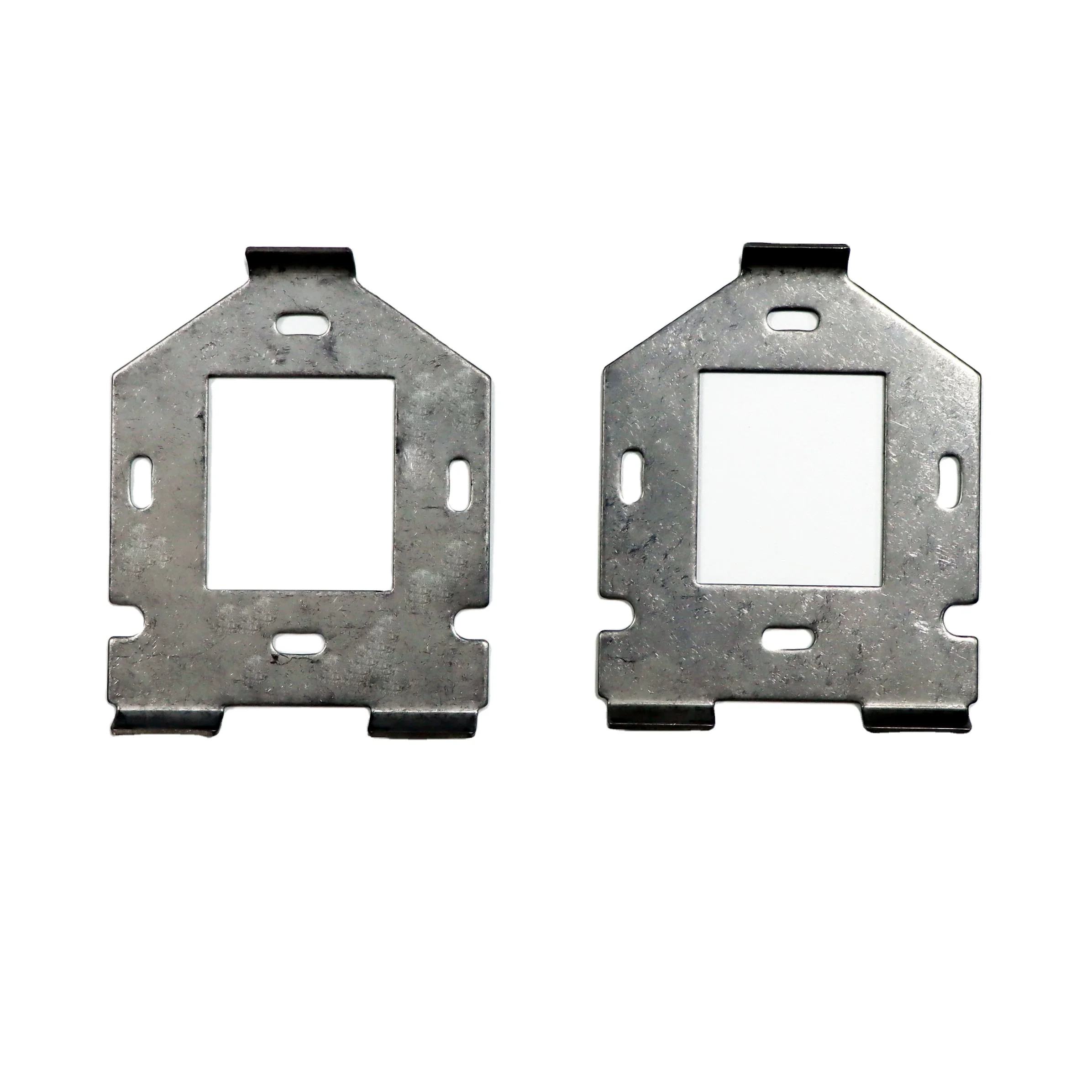

Precision Forging

Precision forging is an advanced forging method that improves the accuracy of forgings and reduces surface roughness. The advantage of this method is that it reduces the machining allowance and dimensional tolerance of the forging, and can make the forging size as close to or equal to the part size as possible.

Refined blanks use precision forging technology to replace rough machining processes, and precision forgings are directly processed to obtain finished parts.

The dimensional accuracy of cold precision forging can reach 0.02-0.05mm. Due to its high-quality, efficient, and low energy consumption characteristics

Typical applications of precision forging include steam turbine blades, straight bevel gears, toothed parts, etc. When using the precision die forging method to manufacture bevel gears, the tooth shape part is directly forged, and only a small amount of grinding is required for the tooth shape part to be used. Due to the reasonable fiber orientation, the service life is greatly improved.

The most obvious characteristics of precision forging are high material utilization rate, high dimensional accuracy, and low surface roughness.

We can provide customers with accessories such as discs, shafts, complex structural components, and blades for applications.