Sheet Metal

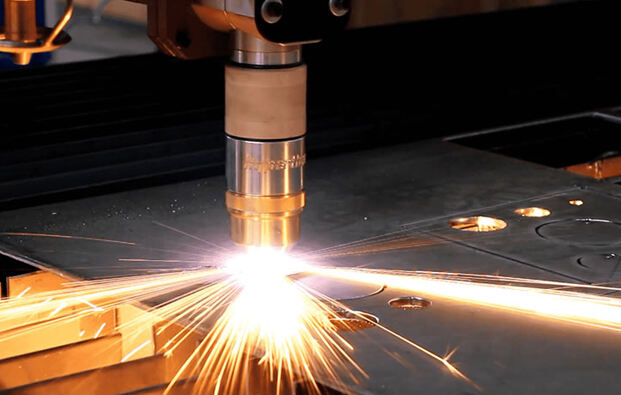

Metal sheet metal processing is called sheet metal processing. For example, using sheet metal to make chimneys, iron barrels, oil tanks, ventilation pipes, elbows, small ends, Tianyuan places, funnel-shaped structures, etc. The main processes include cutting, bending, forming, welding, riveting, etc.

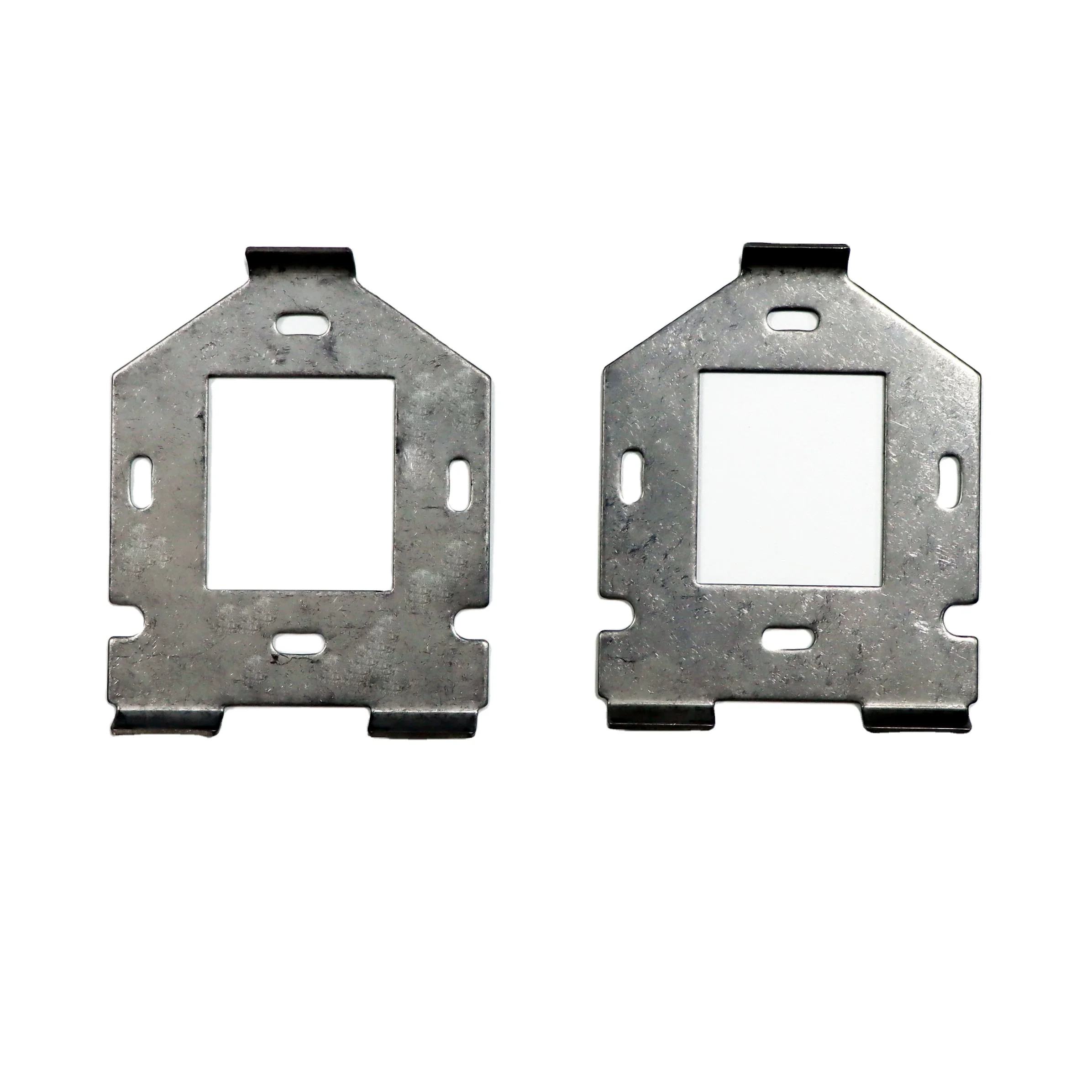

Sheet metal parts are sheet metal hardware parts that can be processed through stamping, bending, stretching, and other methods. A general definition is a part whose thickness remains unchanged during the processing.

Sheet metal processing includes traditional methods and process parameters such as cutting and cutting, stamping and bending, as well as various cold stamping mold structures and process parameters, working principles and operating methods of various equipment, as well as new stamping technologies and processes.

Our sheet metal processing can provide customers with suitable production for small batches and multiple varieties, and the quality of finished products. The quality of stamped parts is very good, not only do they have high precision and flatness, but they also make the product consistent.