Precision Engineering

At SP-MFG, our CNC turning services guarantee unparalleled precision, ensuring every component meets the highest industry standards.

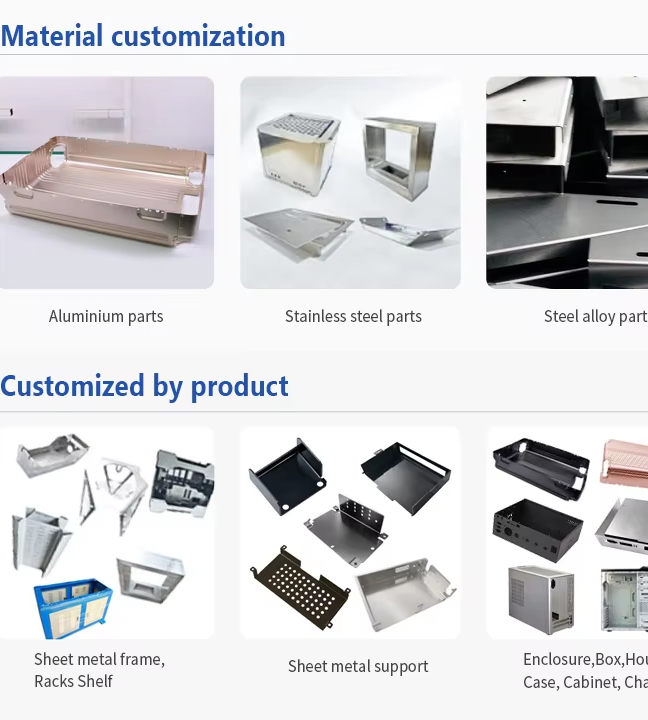

SP-MFG lathe machining parts process is notably versatile, supporting a comprehensive range of materials, including various metals and plastics, thereby accommodating the diverse and often specific material requirements of different industries, ensuring that we can provide tailored solutions for each unique project.

At SP-MFG, they really focus on how fast their lathe machining can be. They offer speeds equivalent to the fastest machines in the world that don’t sacrifice quality in the manufacturing process. In terms of efficiency, this company is second to none when comparing them against others. If you have any urgent machining needs then there’s no better place to go for quick delivery times than at SP-MFG where they have great lathe machining capabilities.

SP-MFG does exceptional work in creating machinery parts made on a lathe that are designed for superior performance and durability. In our services of turning tools we use modern equipment, making every piece very accurate and reliable even under extreme conditions.

At SP-MFG, we make parts on the lathe with exactness and dependability as our main objectives. We use modern technology in our services to achieve tight tolerance levels and outstanding surface finishes during the production of components through lathing; this will allow them work perfectly well wherever they’re applied.

One way to save money without compromising quality is by using lathe machining services provided by SP-MFG. Our effective methods limit wastage of materials and decrease production periods thereby saving the customer a lot of money. If you select us to fulfill your requirements in this area; then rest assured that it’s worth every penny.

Dongguan Shengpeng Precision Technology Co., Ltd. is a design and research, manufacturing as one of the company, engaged in high-end CNC machine parts processing, located in Dongguan City, Guangdong Province, Chashan Town Weixing Road No. 48. With standard modern office building and production workshop more than 2000 square meters.

Our company has carried out ISO9001 quality management system certification, German EPR packaging method and so on. Our factory has more than 10 sets of high-end five-axis equipment imported from Japan, more than 20 sets of CNC lathes and CNC milling machines, and our company has two-dimensional projectors, height meters and three-dimensional testing equipment.

At SP-MFG, our CNC turning services guarantee unparalleled precision, ensuring every component meets the highest industry standards.

With CNC turning, SP-MFG offers versatile manufacturing solutions for a wide range of materials and complex geometries.

Our CNC turning optimizes material usage and reduces waste, providing cost-effective manufacturing solutions for your projects.

From prototypes to large-scale production, our CNC turning expertise at SP-MFG allows for seamless customization to meet your unique specifications.

Lathe machining parts can be produced using a variety of materials, including aluminum, stainless steel, brass, copper, titanium, and various grades of steel. It's important to choose the material based on the specific application and desired properties of the part.

The minimum and maximum size range for lathe machining parts varies depending on the capabilities of the machine shop. Typically, parts can range from a few millimeters to several meters in diameter and length.

Yes, lathe machining parts can be customized to meet exact design specifications. This includes dimensions, tolerances, surface finishes, and any necessary features such as threads, holes, or complex geometries.