Precision Engineering

At SP-MFG, our CNC turning services guarantee unparalleled precision, ensuring every component meets the highest industry standards.

CNC turning at SP-MFG is a highly sophisticated process that involves the utilization of computer-controlled lathes to shape materials by rotating them against precisely calibrated cutting tools, resulting in the production of parts that are not only precise but also symmetrical, meeting the stringent demands of various industries.

SP-MFG services in CNC turning are designed for batch production which is the most efficient way to deal with large order numbers. With our lathe we can machine parts again and again in quick succession without losing accuracy. It means that we deliver a lot of items very fast but this doesn’t affect their quality negatively. The good thing about this approach is saving money for customers who choose us as their partner in batch production – SP-MFG will be your best choice!

The computer numerical control (CNC) turning provision of SP-MFG is second to none in dealing with multifaceted geometries as well as providing a complete answer for complicated part designs. Our sophisticated machinery can produce items having narrow allowances and elaborate shapes which ensures accuracy and uniformity in meeting all your individual requirements from initial sample right through mass production.

The accuracy of SP-MFG CNC turning services in precision engineering is unmatched by any other company. They use advanced CNC lathes to produce components that have never been seen before in terms of their accuracy and surface finish. Our CNC turning capacities can be employed to create parts for aerospace, automotive or medical fields among many others where each piece must be made according to the tightest tolerances possible so it can perform reliably even under extreme conditions.

SP-MFG has a strong focus on CNC turning for custom aluminum parts. Their knowledge and skills in aluminium machining are used to make lightweight and long-lasting components which fit into your design ideas perfectly as well as meet all required performances. Our services also take care of good-looking appearance alongside high functionality of these products whether it is about prototyping or mass production needs.

Dongguan Shengpeng Precision Technology Co., Ltd. is a design and research, manufacturing as one of the company, engaged in high-end CNC machine parts processing, located in Dongguan City, Guangdong Province, Chashan Town Weixing Road No. 48. With standard modern office building and production workshop more than 2000 square meters.

Our company has carried out ISO9001 quality management system certification, German EPR packaging method and so on. Our factory has more than 10 sets of high-end five-axis equipment imported from Japan, more than 20 sets of CNC lathes and CNC milling machines, and our company has two-dimensional projectors, height meters and three-dimensional testing equipment.

At SP-MFG, our CNC turning services guarantee unparalleled precision, ensuring every component meets the highest industry standards.

With CNC turning, SP-MFG offers versatile manufacturing solutions for a wide range of materials and complex geometries.

Our CNC turning optimizes material usage and reduces waste, providing cost-effective manufacturing solutions for your projects.

From prototypes to large-scale production, our CNC turning expertise at SP-MFG allows for seamless customization to meet your unique specifications.

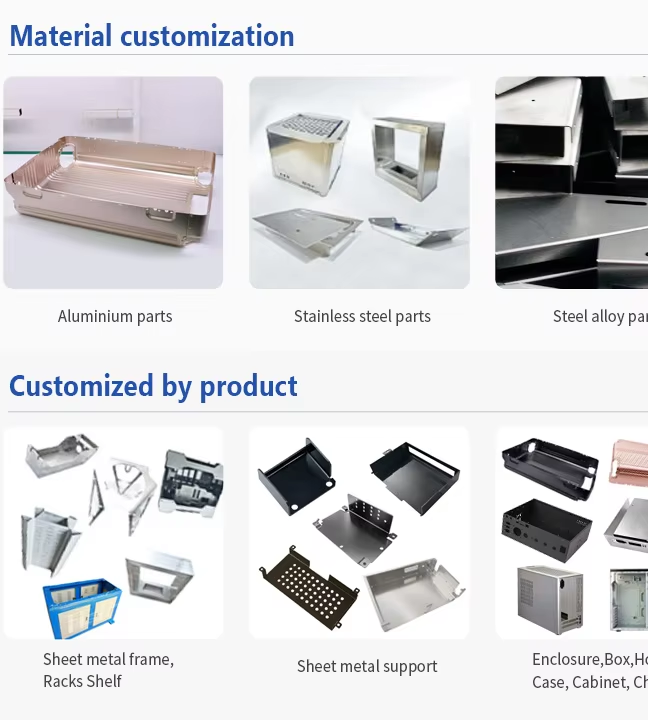

At SP-MFG, we specialize in cnc turning services for a variety of materials including aluminum, stainless steel, brass, copper, and various plastics. Our expertise allows us to work with different grades and specifications to meet specific project requirements.

Yes, SP-MFG provides custom cnc turning solutions tailored to our clients' unique needs. We collaborate closely with our customers to ensure that the final product meets their exact specifications and expectations.

Absolutely, SP-MFG has extensive experience in handling complex cnc turning projects. Our skilled team and advanced machinery allow us to tackle intricate designs and challenging geometries with ease.